What is cellulose ester membrane?

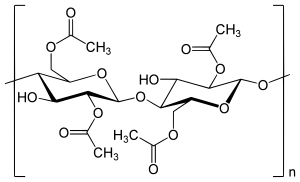

The membrane filters made of cellulose nitrate (CN) or mixed cellulose ester (MCE) also contain a tiny amount of cellulose acetate.

They are advised for a variety of tasks, including sample preparation and aqueous solution filtration.

Structure of the celulose ester membrane ( Cellulose acetate)

Related Double Chin Remover |Ultrasound Cavitation For Double Chin|

What is cellulose ester used for?

These cellulose esters are flexible, biobased polymers can be employed as binders, coated additives, film formers, or modifiers in automotive, wood, plastic, paper and leather coatings, and inks uses.

The use of the cellulose ester membrane cannot be underestimater as they also enable faster production rates, get rid of flaws, and make things look better.

How to use cellulose ester membrane

Why use cellulose esters?

The refined nitrocellulose-based mixed cellulose ester (MCE) filter membrane is hydrophilic, non-toxic, and hygienic.

It also contains the right amount of cellulose acetate, acetone, n-butanol, ethanol, etc.

Related Differences-between-benign-and-malignant-tumours/

The pore size distribution of this porous membrane filter material is compared. uniformly permeable micropores having an absolute pore size of up to 80.

The mixed cellulose ester filtration membrane is also known as an aqueous membrane since it is primarily used to filter aqueous liquids.

This item needs to be sealed, is moisture-proof, fire-proof, and flammable.

Related Can Bitter Leaf Cure Erectile Dysfunction? |Health Benefits of Bitter Leaf|

How to filter aqueous solutions using cellulose ester membrane

- In the electronics industry, fine filtration of water with high purity.

- Calculation of the water pollution index and the analytical determination of oil and particle insoluble in solution.

- Applied to other scientific research departments as well as somatic cell hybridization and mitochondrial ligase prediction heterosis research.

- In the field of medicine and health, the thin membrane method is used to identify E. coli in drinking water, surface water, and well water, as well as human body fluids C-AMP, C-GMP, and blood worms.

- The liquid entering the filter should allow the original air to escape when in use, as doing otherwise will slow down the filtration process.

- The membrane is flammable, resistant to acid and alkali, and resistant to high temperatures of 120 degrees, and is not solvent-resistant. Only aqueous solutions (PH2–10), oil, air, juice, etc. are appropriate. It is important to know if the filter material is on the filter before use.

- The microporous membrane should not be used to filter filtrate that is smaller than 0.025 microns. It can only be partially eliminated and has the sole adsorption to the heat source virus.

- To remove particulates and improve the intrinsic quality and pass rate of the drug while also removing heat-sensitive drugs, the pharmaceutical industry must use autoclaving, water injection, large infusion, Chinese medicine extraction, and beverage filtration (insulin ATP, coenzyme A, and other biochemical agents). Using a 0.45 micron filter and the thin film method of antibiotics, the bacteria were sterilized (or a 0.3 micron, 0.2 micron filter).

- Before filtering liquid, the filter must be wet. If a dry filter results from disinfection, sterilized water must be used to rewet it. All membranes must be sterilized before use even if there is no effect on the filter’s flow rate. Additionally, Escherichia coli uses a nominal pore size of 0.65 m, and the sterilization filtration in the sterile room should be performed in strict accordance with the sterilization operation procedure using a filter membrane with a nominal pore size of 0.45 m, 0.3 m, and 0.2 m.

- When applying vacuum, pressurization, or natural pressure, the bacteria in the outside air are kept from being drawn into the polluted filtrate during vacuuming thanks to and negative pressure. Pressure filtration, also known as faster filtration, should take into account whether the filter’s main body is still intact. Generally speaking, this pressure should not be higher than 0.3 MPa/cm2, although many businesses use this pressure difference.

- Place the filter in the container and wet it with distilled water that is about 70 degrees for a few hours (about 4 hours), after which you should rinse it with distilled water once.

Read also Causes of Lump in Breast-Types and Treatment

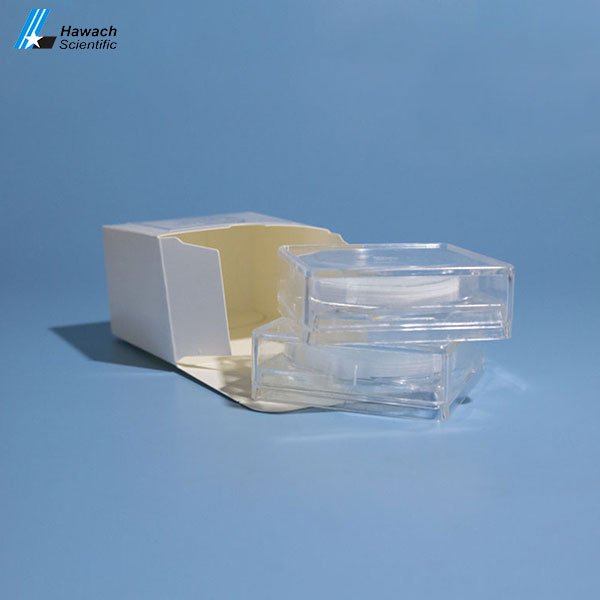

What is A cellulose membrane filter?

Several pharmaceutical processes employ membrane filters.

The most typical applications for cellulose filters are reverse osmosis water systems and microbiological analysis.

Hydrophobic in nature, cellulose membrane filters predominate.

Different cellulose molecules are used to create cellulose membrane filters.

-

How do you use cellulose acetate membrane?

Fibers, polymers, photographic films, lacquers, and reverse osmosis or dialysis membranes all use cellulose acetate.

Although it is possible for other esters to develop (such as cellulose formate, cellulose propionate, and cellulose butyrate), they do not have the same breadth of commercial applications as cellulose acetate.

See Also How to tighten saggy breasts- Causes and remedies

What are Mixed cellulose esters?

Mixed cellulose ester (MCE or MEC) membrane filters are the industry standard for the majority of aerosol sampling applications in industrial hygiene.

They are made of pure, biologically inert mixtures of cellulose acetate and cellulose nitrate.